Production

Our UPCYCLING Process

The regional art houses involved in the UPCYCLING project, such as Haus der Kunst, Lenbachhaus and STOA169 Säulenhalle, have joined forces with MUCARTS to launch this way of sustainably recycling advertising banners. It is therefore a clear statement by all museums and art houses to breathe new life into the exhibition banners of any art event. For this purpose, exhibition banners that have been printed and produced by us over the last 10 years are UPCYCLED into new bag designs. The bags are finished with natural textiles such as cotton and linen to achieve a high value and thus create a long-lasting product.

Banner production and assembly

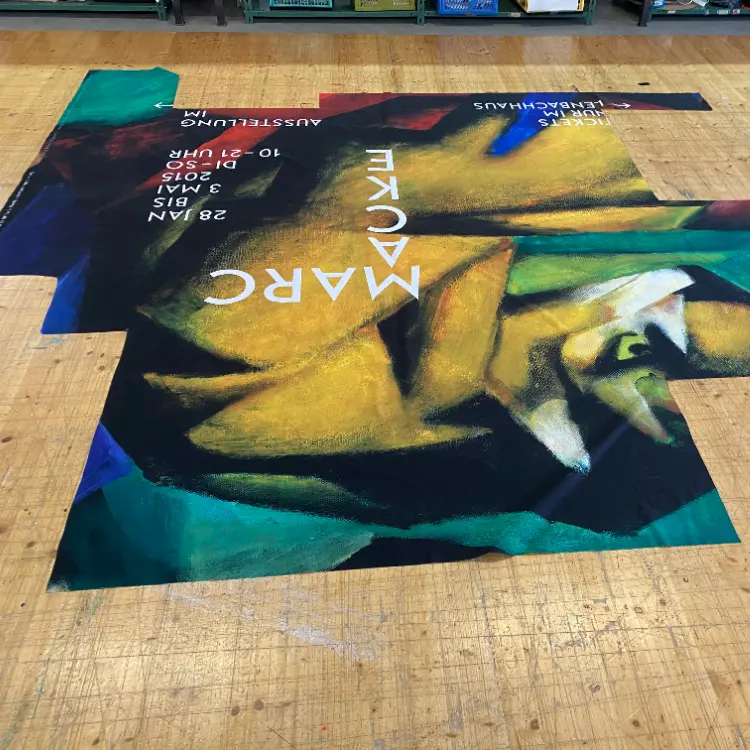

For banner production, the art houses and museums order advertising banners for their exhibitions from MUCARTS. For this, the art house or museum sends a motif of the future art exhibition to MUCARTS. MUCARTS has been buying the PVC material from the same supplier company in Germany for over 20 years. The entire production cycle at MUCARTS is Made in Germany and we are proud of that. Using a weather-resistant and high-quality printing process, the desired artificial banner is printed and placed on hall floors for the drying process. The edges are then folded over and sewn so that no tears can occur during the hanging process. In addition, stainless steel eyelets are hammered into the PVC banner on both sides for hanging. The finished banner is then rolled up and delivered for assembly by MUCARTS. The exhibition banners are hung firmly on the outside walls of the art houses and museums by means of a complex assembly process. They remain there for between 3 and 6 months, depending on the art exhibition. After the exhibition, they are again dismantled by MUCARTS.

Quality of the art banners

After the end of an exhibition, the dismantling begins. During this process, the banners are carefully removed from the art houses. After dismantling, the art banners are carefully stored in the MUCARTS warehouse for production. According to the colours and motifs, new products are designed from the exhibition banners. Our designers and tailors are expertly by our side for the creative and craftsmanship step. Here, the quality of the production and its technical implementation in the manufacturing process play an important role. All products are made of a weatherproof and robust PVC or polyester material on the outside. The inner lining is made of 100% natural linen, which comes from the EU and is fully recyclable. Once the design is ready, unique patterns are created for production.

PROCESS

BY

MUCARTS

Production process

During production, we select specific detailed views from the art banners and combine them in an interesting way to create a new object and create an artefact by combining art and design. First, the required exhibition banner is fetched from the warehouse and spread out on a special wooden floor in the production hall and cleaned. Then the cutting patterns of the respective design are positioned on the PVC banner and carefully marked. Now the cutting can begin. Our trained tailors and seamstresses know their trade and conjure up a high-quality product from the former advertising banners that is both modern and timeless. A signboard for sustainability, art and culture. The patterns are then mainly used to make bags according to the designs. The manufacturing process first involves sewing in the 100% natural linen fabric, the inside pockets and the zips. The pockets are sewn from the inside with a robust thread to protect the seam from external influences in the long term. After production, the product is subjected to another haptic and visual quality control before it is assigned an article number. If everything is perfect, the final product is prepared for sale.

THE

ART

OF

UPCYLING

Finalisation and quality check

When using exhibition banners in the UPCYCLING process and during finishing, traces of use are naturally possible. We are talking here about an art patina, which exudes a natural charm and shows the traces of life and living. Nevertheless, we pay attention to the quality of the individual patterns and materials used. All pattern pieces are neatly sewn together so that the final product is resistant to tension and tearing. With special sewing machines and craftsmanship, we can implement invisible seams on some of our products. This way we protect the seams and guarantee a high durability of the products.

Locations and packaging

Our goods are available in the museum shops in Munich. We do not use plastic packaging and use recycled cardboard boxes for shipping. With our shipping service provider DHL, we ship climate-neutral worldwide with GoGreen.